- #CNC SIMULATOR INFO MANUAL#

- #CNC SIMULATOR INFO FULL#

- #CNC SIMULATOR INFO SOFTWARE#

- #CNC SIMULATOR INFO CODE#

Teachers register their username and password through REGE CNC server, student may login into the network version of REGE CNC in any PC using local area network, Teacher can centralize the management and monitor students over local area network. REGE CNC SERVER MAIN FUNCTION Users management

Embedded all kind of tools in REGE CNC.Management tool and performance parameters adopt database technology.Measure tools : edge finder, feeler gauge, micrometer, calipers etc.Machining with coolant, sound and iron fragment effect.

#CNC SIMULATOR INFO MANUAL#

#CNC SIMULATOR INFO CODE#

#CNC SIMULATOR INFO FULL#

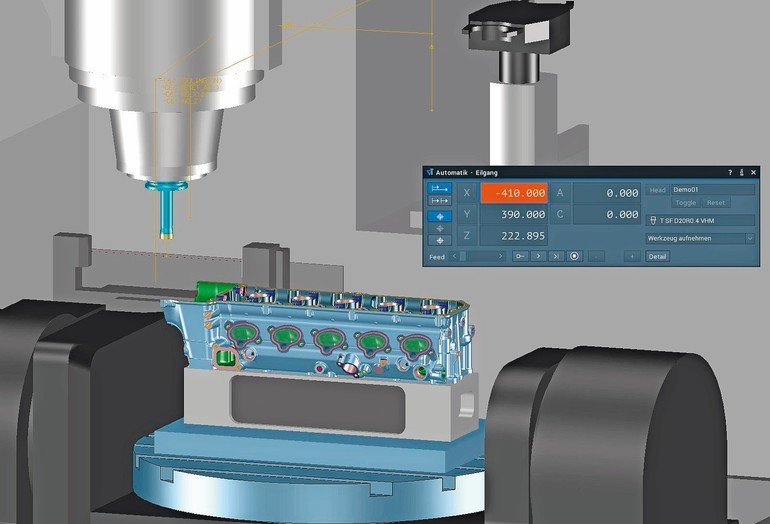

Dynamic rotation, zoom, move, full screen, switch views, etc.3D Modeling based OPENGL, Dual Monitor Display.

#CNC SIMULATOR INFO SOFTWARE#

This software is also the first and the only domestic NC simulation software which can be updated automatically online for free. Teachers recieve real-time operation information from students at any time through network. By using the software in PC, students can master the operation of all kinds of NC lathe, NC milling and machining center in short time. It has programming and processing function for FANUC, SIEMENS(SINUMERIK), MITSUBISHI, FAGOR, HAAS, PA, Romi, GSK, HNC, KND, DASEN, WA ,GREAT,SANYING, RENHE, SKY,JNC,Decekel,GTC2E,NCT,Mazak. Teacher gets students' operation information through CNC Server in real time.ĬNC Simulation includes 22 sorts, 81 systems, and 203 control panels. It can be either programed by hand or imported with CAM NC program and then start simulation in CNC. The functionality of the simulator: preparation of texts of control programs of turning operations in the format of a standard GM code, checking control programs for syntax and technological errors, playing on the computer screen (or other computing device) three-dimensional graphic models of the main components of the lathe machine and metal-cutting tools to simulate the process of turning metal, the three-dimensional visualization of the process of forming parts during turning on the compiled control programs, visualization of toolpaths, implementation of interactive user interaction with the simulation model of technological equipment.REGE CNC is easy to use for both students and teacher. Material processing is performed on two axes in the horizontal plane.įield of application of the software product: educational process using computer technology: laboratory lessons of students in computer classes, distance learning, demonstration support of lecture material in the group of areas of training and specialties: «Metallurgy, Engineering and Material Processing». The basis of the three-dimensional simulation model is a lathe with a classical arrangement of units, equipped with a CNC system, an eight-position turret, a three-jaw chuck, a tailstock, a coolant supply system and other machinery. A software simulator of a numerical control (CNC) lathe is an educational methodological development intended for basic familiarization of novice machine building specialists with the principles of programming parts turning operations using standard GM code (Fanuc System A).

0 kommentar(er)

0 kommentar(er)